Comparing Different Types of Diesel Pumps: Which One is Right for You??

When it comes to choosing the right diesel pump for your needs, there are several factors to consider. From flow rate to power source, each type of diesel pump offers unique advantages and disadvantages. In this article, we will compare different types of diesel pumps to help you make an informed decision. Whether you are a farmer, a construction worker, or simply need a reliable pump for your vehicle, understanding the differences between these pumps will assist you in finding the one that best suits your requirements.

1. Centrifugal Diesel Pumps: Efficient and High-Volume

Centrifugal diesel pumps are known for their efficiency and ability to move large volumes of diesel fluid quickly. These pumps are designed for applications where high flow rates are required. They work by converting rotational energy from an engine or electric motor into kinetic energy, which then moves the diesel fluid through the pump and into the desired location. Centrifugal diesel pumps are commonly used in agriculture, construction, and fire-fighting operations.

2. Diaphragm Diesel Pumps: Versatile and Self-Priming

Diaphragm diesel pumps are versatile and self-priming, making them a popular choice for various applications. These pumps use a flexible diaphragm, driven by an engine or electric motor, to create suction and generate pressure. Diaphragm pumps can handle fluids with high solid content and are often used for transferring diesel fuel, irrigation, and dewatering purposes. They are also suitable for handling abrasive or corrosive fluids.

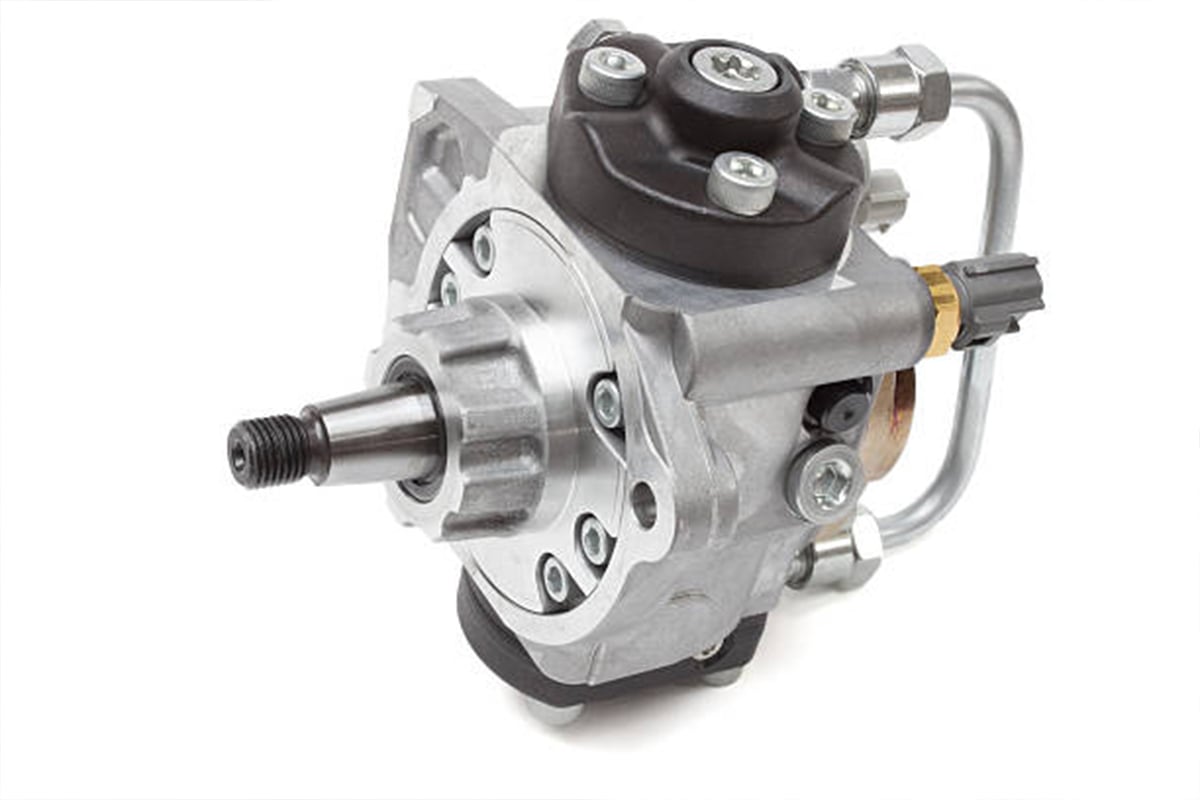

3. Gear Diesel Pumps: Precise and Compact

Gear diesel pumps are known for their precision and compact design. These pumps use a set of interlocking gears to create suction and move diesel fluid. They are commonly used in fuel transfer applications, such as refueling vehicles and equipment. Gear pumps are highly efficient and offer a consistent flow rate. Their compact size makes them ideal for installations with limited space.

4. Rotary Vane Diesel Pumps: Smooth and Reliable

Rotary vane diesel pumps are known for their smooth operation and reliability. These pumps use a series of rotating vanes to create suction and move diesel fluid. They are commonly used in automotive and industrial applications. Rotary vane pumps offer a continuous flow of diesel fluid and are suitable for both high and low viscosity liquids. Their design ensures minimal pulsation and noise levels.

5. Piston Diesel Pumps: Powerful and Durable

Piston diesel pumps are known for their power and durability. These pumps use reciprocating pistons to generate pressure and move diesel fluid. They are commonly used in heavy-duty applications, such as mining, construction, and oil and gas industries. Piston pumps offer high pressure capabilities and can handle fluids with high viscosity. They are designed to withstand harsh operating conditions and provide reliable performance.

6. Submersible Diesel Pumps: Convenient and Submerged

Submersible diesel pumps are designed to be submerged in the diesel fluid, making them a convenient option for certain applications. These pumps are commonly used for draining flooded areas, emptying tanks, and transferring diesel fuel. Submersible pumps eliminate the need for priming and can operate in confined spaces. They are often used in marine, industrial, and agricultural settings.

7. Electric Diesel Pumps: Reliable and Convenient

Electric diesel pumps are powered by electricity and offer a reliable and convenient solution for various applications. These pumps are commonly used in situations where a continuous power source is available, such as in buildings or vehicles. Electric pumps are easy to operate and require minimal maintenance. They are suitable for both small-scale and large-scale diesel transfer operations.

8. Engine-Driven Diesel Pumps: Portable and Versatile

Engine-driven diesel pumps are portable and versatile, making them an excellent choice for remote locations or areas without access to electricity. These pumps are powered by an internal combustion engine, typically fueled by diesel or gasoline. Engine-driven pumps are commonly used in agriculture, construction, and emergency response situations. They offer flexibility and mobility, allowing for easy transportation and use in various environments.

9. Hand-Operated Diesel Pumps: Manual and Portable

Hand-operated diesel pumps are manually operated and offer a portable solution for small-scale diesel transfer needs. These pumps are often used in situations where electricity or fuel-powered options are not available or practical. Hand-operated pumps are lightweight, easy to use, and require no external power source. They are ideal for emergency situations, outdoor activities, and backup fuel transfer.

10. Solar-Powered Diesel Pumps: Eco-Friendly and Sustainable

Solar-powered diesel pumps are an eco-friendly and sustainable option for diesel transfer. These pumps utilize solar energy to power the pump and move diesel fluid. Solar-powered pumps are commonly used in remote locations, off-grid applications, and environmentally conscious projects. They offer a renewable energy solution and help reduce carbon emissions. Solar-powered pumps are reliable, cost-effective, and require minimal maintenance.